Industry 5.0: When to Start Your EU Compliance Journey

30 Sep 2025

How forward-thinking manufacturers can leverage these regulations as catalysts for innovation

The convergence of Industry 5.0 technologies with Europe's rapidly evolving regulatory landscape presents manufacturers with a critical question: when is the right time to begin preparing for compliance? With the EU Machinery Regulation, AI Act, and Cyber Resilience Act all demanding significant organizational changes, the answer is unequivocally now.

The Perfect Storm of Regulation

Europe is fundamentally reshaping how manufacturers must approach product development, particularly for connected and intelligent systems. Three major regulatory frameworks are creating unprecedented compliance requirements:

- The New Machinery Regulation (2023/1230) becomes legally binding on January 20, 2027, introducing enhanced cybersecurity requirements for machinery with digital elements. This isn't simply an update to existing safety standards—it represents a paradigm shift requiring manufacturers to integrate cybersecurity considerations from the design phase onwards.

- The Cyber Resilience Act (CRA), adopted in October 2024, harmonizes cybersecurity standards across all products with digital elements, from household IoT devices to embedded industrial software. Manufacturers must now conduct comprehensive risk assessments, implement automated vulnerability management, and maintain security throughout the entire product lifecycle.

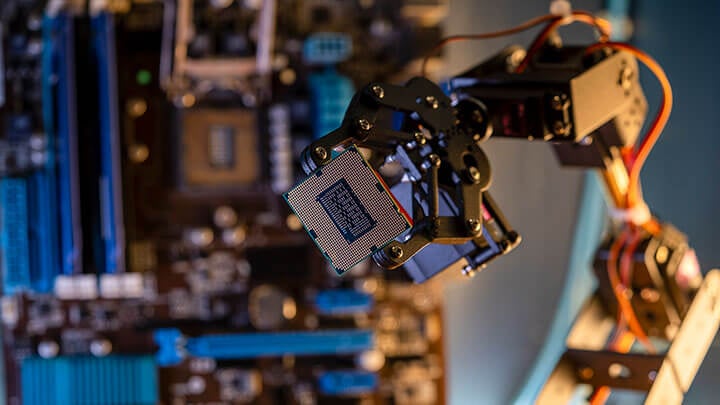

- The EU AI Act, already in force since August 2024, establishes the world's first comprehensive legal framework for artificial intelligence. For Industry 5.0 manufacturers leveraging AI for predictive maintenance, quality control, or collaborative robotics, compliance with high-risk AI system requirements becomes essential.

Why Starting Now Isn't Optional

The implementation timelines might suggest manufacturers have breathing room, but this perception is dangerously misleading. Consider the scope of changes required:

- Product Development Cycle: These regulations don't only demand technical modifications—they require fundamental shifts in how companies approach product development. Security-by-design principles must be embedded into organizational R&D, requiring new processes, training programs, and quality management systems.

- Supply Chain Overhaul: Manufacturers must ensure their entire supply chain meets new cybersecurity and AI governance standards. This involves auditing suppliers, establishing new contractual requirements, and potentially sourcing from entirely different vendors.

- Technical Upgrade: Legacy systems need comprehensive security upgrades, while new products must be designed with built-in compliance capabilities. This often means rethinking fundamental architectural decisions.

The Industry 5.0 Advantage

Manufacturers already embarking on Industry 5.0 transformations have a unique opportunity. The human-centric, sustainable, and resilient principles of Industry 5.0 naturally align with the regulatory emphasis on security, transparency, and responsible innovation. Companies can integrate compliance requirements into their digital transformation initiatives rather than treating them as separate burdens.

The convergence creates competitive advantages for early movers. While competitors scramble to meet minimum compliance requirements, forward-thinking manufacturers can leverage these regulations as catalysts for innovation, developing more secure, transparent, and sustainable operations that exceed regulatory baselines.

Strategic Implementation Timeline

- Immediate Actions (2025): Begin comprehensive gap analyses against all three regulatory frameworks. Establish cross-functional compliance teams combining cybersecurity, AI governance, and traditional safety expertise. Start pilot projects integrating security-by-design principles.

- Short-term Priorities (2025-2026): Develop new organizational processes, begin supplier audits, and initiate technical upgrades for critical systems. Focus on high-risk AI applications and machinery with significant digital components.

- Medium-term Execution (2026-2027): Complete technical implementations, finalize supply chain transitions, and conduct comprehensive testing and validation. Prepare for the January 2027 Machinery Regulation enforcement.

The Time is Now

Industry 5.0 represents the future of manufacturing—human-centric, sustainable, and resilient. Europe's regulatory framework isn't an obstacle to this future; it's the foundation ensuring this transformation occurs responsibly and securely.

The question isn't whether your organization needs to prepare for these regulatory changes—it's whether you'll approach compliance as a strategic opportunity or a last-minute scramble. With less than two years until key deadlines, manufacturers who begin their compliance journey now will emerge as leaders in the Industry 5.0 era.

The convergence of technological innovation and regulatory evolution creates unprecedented challenges, but also unprecedented opportunities. The time to start is now.